We have always made a point of honor to improve our products, that the microlights coming out of our production lines no longer have much to do with those of the 80s.

Our current projects

Towards new electric horizons

Towards new electric horizons

After the success of our first electric ultralight, the adventure continues... Driven by our commitment to more sustainable skies, we are now working on an ambitious project that promises to open up new horizons for light aviation.

Our new objective? To take electric air mobility to the next level, by developing a range that will meet the expectations of pilots and enthusiasts in search of new sensations. Supported by the French government, the Auvergne-Rhône-Alpes region and the BPI as part of the France 2030 program, this project is shaping the future of light aviation: silent, environmentally-friendly and accessible.

There are still a few secrets to be revealed, but one thing is certain: Air Creation is ready to push back the boundaries of innovation to reinvent flight.

Our major innovations

e-PixeL: the first step towards electric skies

It's a beautiful story that began with a dream: to fly lightweight, silent and environmentally-friendly machines. With the e-Pixel project, Air Creation has taken an unprecedented step in the ULM world, marking the start of a new and ambitious era.

When we first came up with the idea of developing an electrically-powered microlight, we knew it would be a major challenge. Finding a powerful, compact and reliable electric motor, while guaranteeing sufficient range for the pleasure of flight, without compromising our signature performance, safety and agility: this was the adventure our team embarked on with passion and determination.

After years of research, testing and hard work, e-Pixel was born. A first flight, then another: each take-off validated months of effort and collaboration. Today, e-Pixel has become the first electric ultralight to be approved by the DGAC. A source of pride for us all, and a symbol of our commitment to making flying greener.

But for us, e-Pixel is much more than a technical project: it's a milestone that inspires us to dream even bigger.

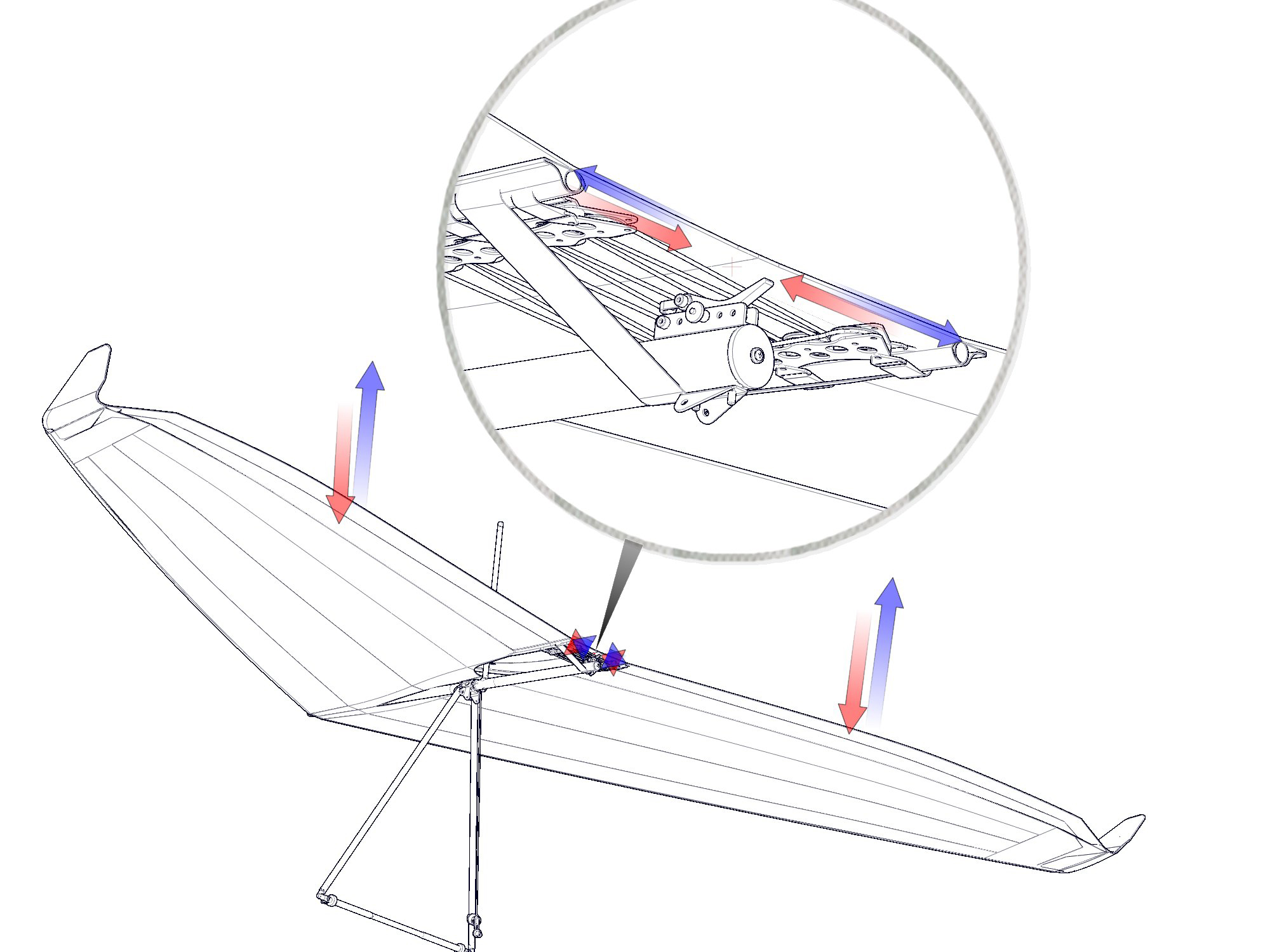

Quick-folding wings

With the D.S.T.E. wings (Double Surface with External Transversal) and equipped with rigid struts, Air Création has developed the Short Pack system, a system intended to simplify the assembly and the disassembly operations of the wing. The system allows a single person to fold the wing onto the trike in just a few minutes. A simple and economical option to avoid parking problems.

Corset System ©

Developed at the end of the 2000s, the appearance of variable configuration wings is a real revolution in the weight-shift controlled aircraft, the Corset technology invented by Gilles BRU open a whole new flight domain to pilots.

The pursuit of performance has brought the generalization of trim systems which make it possible to vary the cruising speed.

The flex-wing wings roll reaction is proportional to their flight speed, making the wing unwieldy at low speeds and conversely too sensitive at high speeds. This implies that conventional design fast wings are unable to make slow approaches and land in a short distance in turbulent conditions.

The Corset system patented by Air Creation is the answer to this problem:

It combines exceptional ease of use to remarkable effectiveness. It allows to control the cruising speed and at the same time adapt the wing geometry to this new speed. By acting on the billow, the twist and the central wing profile, it reconfigures itself like those of a bird.

Slow flight :

Either the approach, the landing phases or to increase the rate of climb, a slow speed range is recommended.

In this case the tension is released, it has the effect of twisting the wing tip, increasing the central profile prominence as well as the billow. This action decreases central reflex and move forward the center of thrust. All these modifications to the wing profile, makes it possible to decrease the cruising speed but also to improve the maneuverability in roll, safe maneuvering at large incidences and increase the wing lift coefficient.

high speeds :

In order to travel, to cruise or simply to counter strong winds, it is more convenient to adopt a high-speed range.

For this we increase the tension which has the effect of reducing the twist at the wing tip, decreasing the central profile prominence as well as the billow. This action increases the central reflex and retract the center of thrust. All these modifications to the wing profile, make it possible to obtain a high cruising speed but also reduce the drag attributed to the wing, ensuring the perfect pitch preservation and improve the roll stability.

Mechanically welded steel frame

While most trikes are made of an assembly of tubes linked together by screws or rivets, our teams are developing a welded frame, thus reducing weight and increasing structural strength at the same time.

This new advance allows better crew protection because this lattice structure has a strong capacity to absorb shocks through deformation. This technology was developed for the Tanarg and has become the reference for our models.

CAD/DAO development

In many branches, the arrival of computers is a real revolution, already used for the design of the GTE range in the early 90s, it was in the 2000s that this tool was used to its full potential, we allowing to design the Tanarg, the first tricycle designed entirely by computer, thus optimizing ergonomics and aerodynamics.

Pyrotechnic rescue parachute intergration

In the 90s we adapted the tricycles to accommodate a ballistic rescue parachute, a complete system was then designed to be able to secure and bring the aircraft and its crew back to the ground. In 1989, we were the first manufacturer to carry out a test in real conditions, demonstrating the smooth running of the opening sequence.

Oleo-pneumatic shock absorber installation

While the first trikes were not absorbed, many of them were damaged during hard landings, especially with flight schools, the replacement of landing gear was frequent at this time. With the design of the GT-Bi, in early 90s, we incorporates Fournales © oleo-pneumatic rear shock absorbers.

The innovation we have demonstrated does not stop with our microlights, it also intervenes in the design and manufacturing methods. We make every effort to facilitate the work of the teams and improve its quality. With this in mind, we have equipped ourselves over time with increasingly advanced technology and have developed bespoke solutions.

underfloor workstation

CAO/DAO

tools

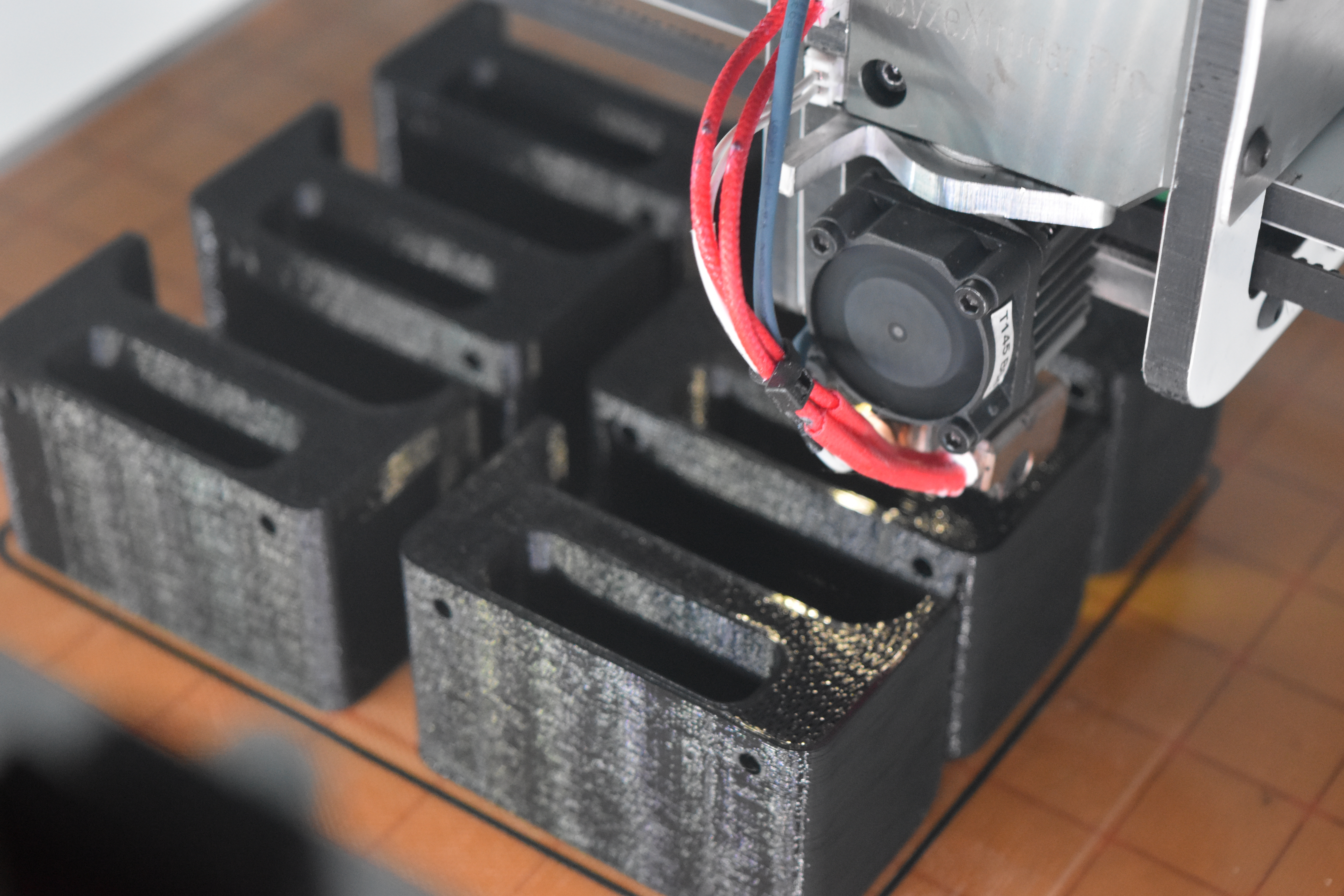

3D printing technologies

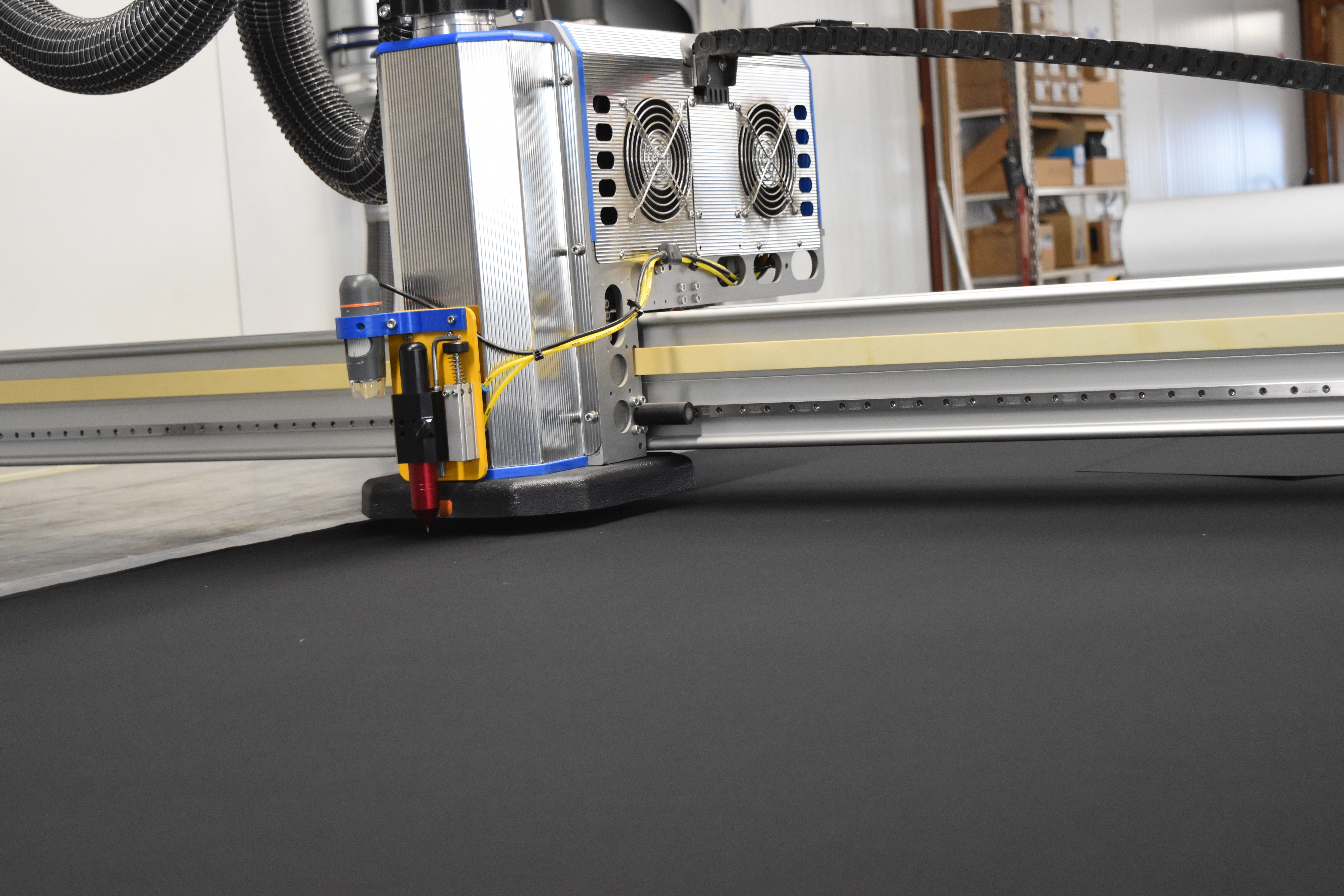

Lazer cutting

machine